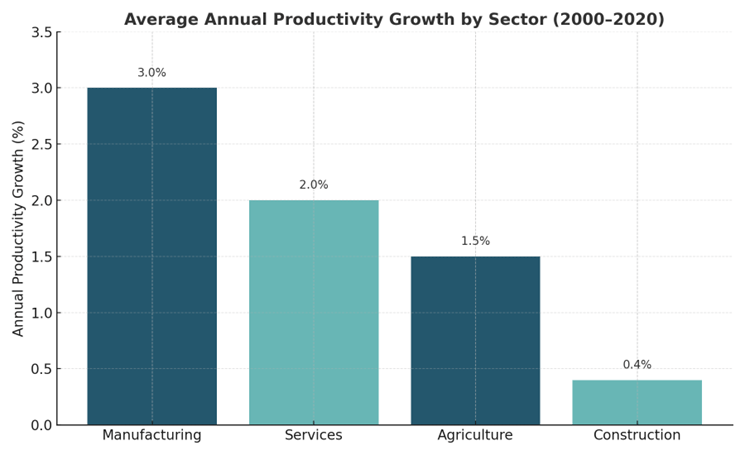

Over the past several decades, productivity growth has transformed industries such as manufacturing, services, and agriculture. These sectors experienced significant efficiency gains through automation, digitalisation, and globalisation.

By contrast, the construction industry has consistently lagged behind. While manufacturing productivity has more than doubled since 1970, construction productivity has actually declined by over 30% in the same period. According to data published by the Bureau of Labor Statistics (BLS), productivity growth in the construction industry has been the slowest among all major industry categories since at least 1987, when the current estimates begin. Productivity growth was actually negative on average for the construction industry over the 1987 to 2019 period, whereas it averaged at least 1 percent per year in all other major industries.

The scale of this decline is stark. Real output per worker in 2020 was more than 30 percent lower than in 1970, following one of the most persistent productivity declines in any major industry. Projects frequently run over budget and beyond schedule, with minimal improvement in delivery performance across decades.

This gap signals that the construction industry is ripe for innovation. With the introduction of AI and related digital technologies, construction stands at the threshold of a long-awaited transformation.

Figure 1. Average annual productivity growth by sector (2000–2020). The construction sector underperforms peers, creating headroom for AI‑enabled gains.

Why Productivity Matters — and How It Is Measured

Productivity is generally measured as output per unit of input (e.g., GDP per hour worked). In construction, this reflects how effectively labour, equipment, and materials are turned into completed assets such as roads, railways, and power plants.

– High productivity growth → means faster delivery, lower costs, and greater value for both investors and society.

– Low productivity growth → means projects are more expensive, take longer, and ultimately weigh down the economy.

The implications extend beyond individual projects. Looking to 2040, the outlook is hardly encouraging. Across advanced economies—and in China—overall workforce projections are near zero or negative because of aging. This demographic challenge makes productivity improvements even more critical for meeting future infrastructure demands.

Beyond project delivery, productivity also shapes profitability. Construction is a low-margin industry, with typical profit margins of only 2–5%. Even modest productivity improvements through AI adoption could ease this pressure, making firms more resilient and financially sustainable. Stronger margins would also create headroom for innovation, research, and capability building, while making the sector more attractive to investors and new entrants.

AI’s Potential in Construction

AI offers a once-in-a-generation opportunity to improve efficiency in construction through three key areas:

Execution Phase

AI-powered planning, scheduling, and resource allocation can optimize project workflows and reduce waste. Machine learning algorithms can analyze historical project data to predict optimal resource deployment and identify potential bottlenecks before they occur.[1]

Monitoring Phase

Automated progress tracking, risk detection, and predictive maintenance enable real-time project oversight. Computer vision and IoT sensors can continuously monitor construction sites, automatically detecting safety hazards, quality issues, and schedule deviations.

Maintenance Phase

Optimised lifecycle management of infrastructure assets through predictive analytics. AI systems can analyze structural health data to predict maintenance needs, extending asset life and reducing long-term costs.

At the project level, these improvements could translate into 10–20% overall savings.

– Conservative case (10%): Achievable with current AI adoption trends and proven technologies

– Ambitious case (20%): Possible with full integration across the construction lifecycle and advanced AI implementation

| Phase | Potential Productivity Gain (%) | Key AI Levers |

| Execution | 8–12% | Scheduling, robotics, modularization, material optimization |

| Monitoring | 5–7% | AI site scans, predictive safety, quality control automation |

| Maintenance | 3–5% | Predictive maintenance, digital twins, automated inspections |

Insights from Industry Studies

McKinsey highlights that construction offers the highest ROI for AI adoption but remains slow to act, held back not by technology, but by structural and organisational barriers.

By contrast, BCG finds that while many firms adopt AI strategies, fewer than 25% achieve measurable results. The main issue is outdated workflows, as firms add AI to existing processes instead of redesigning them. Its three stages — Deploy, Reshape, and Invent — show that real impact requires scaling beyond pilots.

Taken together, these perspectives highlight complementary truths:

- McKinsey stresses the need for systemic capability building and structural transformation.

- BCG highlights workflow redesign and maturity scaling as the practical route to impact.

The common thread is clear: AI’s productivity promise in construction will not be realised through isolated tools or pilots but through organisation-wide change, data discipline, and redesigned workflows.

While the percentage improvements cited — whether McKinsey’s 10–20% project-level savings or BCG’s staged 10–30% productivity gains — illustrate compelling potential, they remain projections and should be treated with caution.

Notwithstanding that, the case for AI adoption in construction is strong: if deployed correctly, AI can materially improve productivity, strengthen project management, and enhance execution certainty. The industry’s track record shows that digital adoption has been slow, but without a decisive shift, construction will continue to lag other sectors, and public projects will grow ever more costly over time. AI adoption is therefore not optional — it is essential for aligning productivity, competitiveness, and societal value.

Lessons from Nuclear Power Projects

Nuclear power plants are among the most complex construction projects in the world, making them a powerful lens through which to examine construction productivity challenges. These megaprojects involve intricate engineering, stringent safety requirements, and massive coordination efforts.

Despite decades of technological advancement in project management tools, engineering software, and construction techniques, delays remain persistent.

| Project (Output) | Planned (Years) | Actual / Projected (Years) | Delay (Years) | Notes |

| Kori (3.1 GW) | 13 | 14 | 1 | South Korea |

| Cattenom (5.2 GW) | 10 | 13 | 3 | France |

| Hinkley Point C (3.2 GW) | 9 | 15+ | 6+ | UK, ongoing |

All projects faced delays despite advances in technology and management, showing that construction innovation has not kept pace with demand.

Why This Matters for the Future

Global electricity demand is projected to increase sharply in the coming decades due to:

- Demographic Pressures: Population expected to surpass 9.7 billion by 2050

- AI and Data Center Expansion: Unprecedented demand for specialized facilities and energy

- Electrification and Clean Energy Transition: Requires substantial new power generation and grid infrastructure

If nuclear and other megaprojects continue to suffer delays, there will be a serious mismatch between energy demand and supply. AI adoption in construction could help close this gap by ensuring faster, more predictable delivery of critical infrastructure projects.

Economic & Social Benefits

Even under a conservative adoption scenario (10% productivity improvement), savings from AI adoption in megaprojects such as Hinkley Point C could reach £1.5–2.5 billion. In a high-adoption case (20%), the figure could double to £3–5 billion.

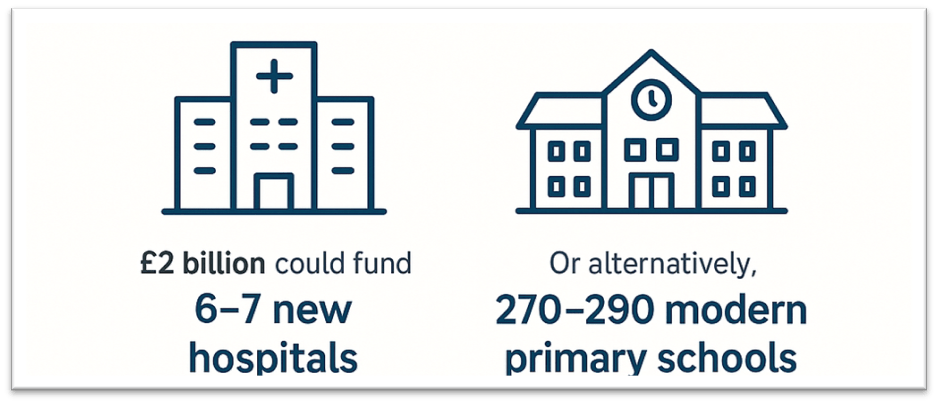

Illustrations:

– £2 billion could fund 6–7 new hospitals[2]

– Or alternatively, 270–290 modern primary schools (based on DfE benchmarks)[3]

These examples highlight how AI-driven construction savings could directly translate into healthcare capacity and educational expansion.

Implementation Challenges and Considerations

While the potential for AI in construction is substantial, successful adoption will require addressing key challenges:

– Workforce Adaptation: Reskilling in AI-augmented workflows

– Regulatory Framework: Updating codes to account for AI-driven processes

– Initial Investment Costs: Substantial upfront capital required

– Data Quality and Integration: Need for reliable, standardized project data

Looking Ahead

This finding has shown how the construction industry, long hampered by declining productivity, could achieve significant efficiency gains through AI adoption. The nuclear power sector illustrates persistent challenges that threaten infrastructure delivery and the transformative potential of AI.

The convergence of demographic pressures, AI development demands, and clean energy transition creates an urgent need for construction productivity improvements.

In the next article, we will explore how AI can be applied across the entire construction lifecycle — from contract drafting and planning to execution, monitoring, and maintenance — as well as the specialized infrastructure needed to support AI development itself.

Sources and References

- Bureau of Labor Statistics. (2024). “Construction Labor Productivity.” U.S. Bureau of Labor Statistics.

- Boston Consulting Group. (2025). Digital and AI in Nordic Construction. Retrieved from https://www.bcg.com/publications/2025/digital-and-ai-in-nordic-construction

- Federal Reserve Bank of Richmond. (2025). “Five Decades of Decline: U.S. Construction Sector Productivity.” Economic Brief 25-31.

- McKinsey & Company. (2024). “Delivering on Construction Productivity Is No Longer Optional.” McKinsey Insights.

- OpenAsset. (2025). “The Top 23 Construction Industry Trends for 2024.” Industry Report. Retrieved from: https://openasset.com/resources/construction-industry-trends/

- ScienceDirect. (2025). “Reexamining Lackluster Productivity Growth in Construction.” Construction Economics Journal.

- U.S. Bureau of Labor Statistics. (2024). “What’s Behind the Projected Construction Employment Growth from 2023 to 2033.” Beyond the Numbers.

- United Nations. (2022). “World Population Prospects 2022.” Department of Economic and Social Affairs.

This article represents an analysis of current industry trends and productivity data. Productivity improvement estimates should be considered indicative rather than guaranteed outcomes, as actual results will vary based on implementation quality, project complexity, and market conditions.

[1] For example, AI can analyze past concrete strength data to help QA/QC engineers predict when the mix will reach its 7-day strength, allowing them to adjust curing or scheduling in advance to prevent delays.

[2] The Midland Metropolitan University Hospital (Smethwick) had an approved cost of around £297 million. This benchmark is used for comparison purposes; actual final project costs may vary. At this scale, £2 billion equates to approximately 6–7 hospitals

[3] Department for Education (DfE) tender benchmarks estimate the cost of building a new primary school at around £6.9–7.4 million (based on ~400 pupils). Using this measure, £2 billion equates to around 270–290 schools.

Leave a comment